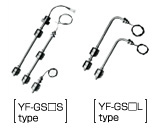

Float type level switches

- Compact float type level switch made of SUS that can detect multiple points

-

Compact float switch without a terminal box. Can detect liquid levels at multiple points (1 to 4 points).

Can be made to meet special requirements and for use at high temperature. The series can be made intrinsically safe and explosion-proof by combining it with a relay isolator.

Features, keys |Usage, use examples |Standard specifications

Features, keys

|

|

Usages, use examples

- Detect levels of water, oil, and various liquid chemical agents

- Control liquid levels at multiple points (control pumps, set upper and lower limit alarms, etc.)

Standard specifications

| Model name | YF-GS□S | YF-GS□L | |

|---|---|---|---|

| Connection | Dimensions | G1/8 | |

| Materials | SUS304 | ||

| Float | Outside diameter | Φ28xH27 | |

| Materials | SUS304 | ||

| Measurable specific gravity | 0.8 or more | ||

| Stem | Outside diameter | Φ8(when L dimension is 600mm or more or 3 contact points are used Φ9) | Φ8 |

| Materials | SUS304 | ||

| Length dimension (Max.) | 1000mm | ||

| Electrical ratings | Contact point capacity | DC 50W/AC 70VA | |

| Maximum open/close voltage | 350V DC, 300V AC | ||

| Maximum open/close current | DC 0.7A/AC 0.5A | ||

| Others | Maximum number of points detected | 4 | 2 |

| Float withstanding pressure | 2.0MPa | ||

| Operating temperature (heat resistant type) | -10 to 100 degrees (180 degrees) | ||

| L1 dimension (min) *1 | 25mm | 50mm | |

| L dimension (min) *:2 | 55mm | 80mm | |

| Setting distance dimensions (min) *3 | 37mm | ||

| L-Ln dimension (min) *4 | 30mm | ||

*1: The Ln dimension means a length from the set position to the bottom of the screw.

*2: The L dimension means the total length from the bottom of the screw.

*3: Setting distance dimensions refers to the minimum dimension when two stoppers are used.

*4: The L-Ln dimension refers to the difference between the final setting position (Ln) and total length.

Note: The values for *3 and *4 are true when the specific gravity of the liquid is 1.0.