The switch captures the electrical difference between empty and full of material to detect the level. When material is empty, electrical status of detecting electrode and grounding electrode is: resistance (Ro) is infinite, and capacitance (Co) will be specific capacitance value determined by installation status.

What are the level switch and level meter?

What are level switches, level meters and level sensors? Where are they used?

This page explains how level switches, level meters, and level sensors are used in various locations including industrial factories and plants.

What are level switch and level meter?

Importance of level switches and level meters

Introduction of level sensors with various operating principles

What are level switch and level meter?

Factories, plants, various equipment, rivers, and utility water tanks all need to monitor and control the levels and remaining volume of liquids, powder, or granulated materials. Level switches and level meters detect and measure materials such as liquids, powder, and granulated materials in tanks, vessels, and plumbing.

What is level switch?

A level switch is a sensor that detects the presence of liquids, powder, or granulated materials at a specific location.(It is also referred to as level sensor) For example, when a tank is supplied with liquid, it overflow.In order to prevent overflows, a level switch is installed near the top of the tank. When the liquid touches the level switch, it outputs a signal to keep the liquid from overflowing the tank. (To detect that a tank is filled with material is referred to full detection, or upper limit detection.) On the other hand, when the liquid level drops as the liquid is discharged, a level switch is used to prevent completely draining the tank. This is referred to as an empty detection or lower limit detection.

What is the level meter?

Different from level switches, level meters these devices continuously measure the volume of liquid, powder, or granulated materials. (This is also referred to continuous level meter, liquid meter, or powder meter.) Although a level switch can detect the presence of material at a certain point, a level meter outputs a reading of the total liquid volume in a tank, usually from 0 to 100%. So, a level meter can monitor and control the volume in greater detail than a level switch. The level meter usually outputs its reading as a small current of 4 to 20mA. (4mA represents 0%, 20mA represents 100%, and 12mA represents 50%,)

Importance of level switches and level meters

As production facilities put more emphasis on energy saving, they are using lots of various types of sensors.

Among these types of sensors, level sensors are used in harsh conditions with extreme temperatures, pressures, vibration, and surrounding environments. The objects measured by level sensors are greatly diversified. Under these conditions, level sensors are required to be extremely reliable. Our level sensing equipment meets these requirements. They are manufactured using lots of experience and technical skill. We are proud of their quality and reliability.

Introduction of level sensors with various operating principles

However, you cannot detect substances if you do not select optimum sensor depending on substance to detect (liquid, or powder) and detecting conditions (use temperature, etc.).

This page describes which method and which product (level switch or liquid meter) is best for the substances and conditions you want to detect, taking some typical examples.

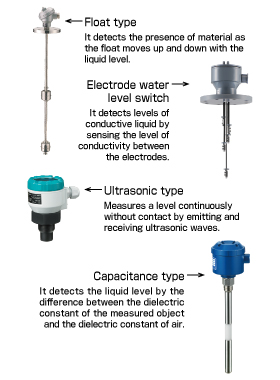

Detecting liquids (liquid level meter, water level meter)

Typical examples for measuring and detecting liquids are as follows:

- Float type

: Uses a float that rests at the water level - Electrode water level switch

: Uses the principle that current flows through the electrodes - Cable float type

: Uses a float that rests at the water level - Capacitance type

: Uses the dielectric constant of the liquid - Ultrasonic wave type

: Uses reflection of an ultrasonic wave - Pressure type (Submersible hydrostatic type)

: Uses pressure (water pressure) of the liquid - Guided radar type

: Uses the principle of micropulse reflection - Capacitance type

: Uses the dielectric constant of the liquid

< level switch >

< Liquid level meter / water level meter >

And so on.

Each type has advantages and disadvantages. Therefore, we must choose the detection method depending on the liquid type and conditions of use.

Features of each method and precautions for selection are described below.

Switch

| Method | 1. Float type liquid level switch |

2. Electrode type liquid level switch |

3. Cable float type liquid level switch |

4. Capacitance type liquid level switch |

|---|---|---|---|---|

|

|

|

|

|

| Principle | A float moves up and down due to buoyancy. A reed switch is actuated by a magnet in the float, and outputs a detection signal | When the conductive liquid touches between the electrodes, a current flows through the electrodes, detects it, and outputs a detection signal. | The float moves up and down according to the principle of buoyancy, and the magnet inside the float activates the reed switch to output a detection signal. | Detects and measures the difference between a material’s specific capacitance dielectric constant and the present liquid’s dielectric constant to detect the liquid level and output. |

| Advantages | Low cost and easy to use. | Can be used at low cost. The length of the electrode can be changed by the customer. | Low cost and easy to use. | Can detect and measure under hard conditions of high temperature and high pressure.It can also measure highly viscous liquid. |

| Disadvantages | May not be used for viscous liquid, liquids of low specific gravity, or in high temperature or high pressure situations | Cannot be used for fully insulating liquids. The size of the connection is large. Weak to adhesion. | may not be used in highly viscous liquids, light specific densities, high temperature and high pressure places. | Cannot measure when the dielectric constant of the liquid changes. |

| Related links |

Production information Special examples of use |

Product information | Product information |

Production information Special examples of use |

See here for liquid and water level switched with other methods

Liquid level meter / water level meter

| Method | 5. Ultrasonic type liquid type level meter |

6. Pressure type liquid level meter(Submersible hydrostatic type) |

7. Guided radar type liquid level meter |

8. Capacitance type liquid level switch |

|---|---|---|---|---|

|

|

|

|

|

| Principle | Emits an ultrasonic wave and receives it after it is reflected off the liquid surface. Then it converts the time difference between sending and receiving the wave to a measuring signal and outputs the data. | Install it in the lowest position of a tank and it detects liquid pressure and outputs the results. | Emits an microwave and receives it after it is reflected off the liquid surface. Then it converts the time difference between sending and receiving the wave to a measuring signal and outputs the data. | Detects and measures the difference between a material’s specific capacitance dielectric constant and the present liquid’s dielectric constant to detect the liquid level and output. |

| Advantages | Measure without contact material. Easy to handle. | Easy to use. | Not affected by environmental changes. Supports storage tanks and large silos. | Can detect and measure under hard conditions of high temperature and high pressure.It can also measure highly viscous liquid. |

| Disadvantages | Cannot be used in vacuum.May not be used under high temperature, high pressure, vapored, dusty environment, and obstacles. | May not measure at high temperature and high pressure as difference may be large.With a continuous indicating type, the sensor shall be installed at lower position of a tank | Not suitable for small tanks and narrow spaces. It may malfunction due to bubbles. If the permittivity is low, it may not be possible to measure. | Cannot measure when the dielectric constant of the liquid changes. |

| Related links | Production information Special examples of use |

Product information | Product information | Production information Special examples of use |

See here for liquid and water level meters with other methods

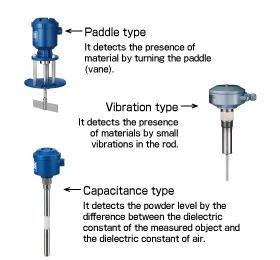

Level switch and level meter for powder

Typical examples for measuring and detecting powder and granulated materials

- Paddle type

: Uses the principle of slowing or stopping a rotating vane - Vibration type

: Uses the principle of attenuation of a vibrating bar - Capacitance type

: Uses the dielectric constant of the powder - Ultrasonic wave type

: Uses reflection of an ultrasonic wave

< level switch >

Each type has advantages and disadvantages. Therefore, we must choose the detection method depending on the liquid type and conditions of use.

Features of each method and precautions for selection are described below.

| Method | 1. Paddle type (switch) |

2. Vibration type (switch) |

3. Capacitance type (switch, continuous) |

4. Ultrasonic wave type (switch, continuous) |

|---|---|---|---|---|

|

|

|

|

|

| Principle | A shaft with a vane at the end rotates. When the vane touches material, the vane stops rotating and outputs a detection signal. | A rod vibrates at a specific frequency. When material touches the rod the vibration is attenuated. The unit detects this attenuation and outputs detection signals. | Detects and measures the difference between a material’s specific capacitance dielectric constant and the air dielectric constant to detect a level and output it. | Emits an ultrasonic wave and receives it after it is reflected off the liquid surface. Then it converts the time difference between sending and receiving the wave to a measuring signal and outputs the data. |

| Advantages | Low cost and easy to use. | Can detect even physical property is changed.No need for initial adjustment and maintenance. | Can detect and measure under hard conditions of high temperature and high pressure. Also can measure adhesive powder and granulated materials. | Measure without contact material |

| Disadvantages | As this is mechanical type, it may need maintenance. Cannot be installed at location with much vibration. | Cannot be used in locations with a lot of external vibration, at high temperatures, or under high pressure. | Cannot measure levels if the dielectric constant of the material changes | Cannot be used in vacuum.May not be used under high temperature, high pressure, vapored, dusty environment, and obstacles. |

| Related links | Production information Special examples of use |

Production information Special examples of use |

Production information Special examples of use |

Production information Special examples of use |